The average general aviation aircraft is more than 30 years old (FAA). As airplanes get older, the risk of airframe corrosion increases dramatically. Symptoms may not be noticeable until the damage is done.

Protect your plane

CorrosionX Aviation

Used & endorsed by all major manufacturers

American Eurocopter, Boeing Helicopters, Cessna NASA, Raytheon Aircraft, Petroleum Helicopters, Saab Aircraft, Vertex Aerospace, US Airforce, US Army, US Navy, US Coast Guard

MIL-SPEC PROTECTION FOR YOUR AIRCRAFT

CorrosionX Aviation

World's most trusted aircraft corrosion prevention and control material

One of only two products approved under MIL-PRF-81309H Type IV

Recommended by Joint Council on Aging Aircraft, whose testing proved it more than twice as effective as any other product

ZERO volatile organic content

Navguard

Ultra thin film corrosion preventive compound developed by US Naval Air Systems Command

Meets MIL-PRF-81309F Type I, II & IV

Displaces water & prevents corrosion

Low build treatment, won't attract dust & dirt

Unsurpassed high performance multi-metal protection – ferrous metal, aluminum, magnesium and their alloys

Does not penetrate or migrate like CorrosionX

PRODUCT INFO

CorrosionX Aviation is the world's most trusted & proven aircraft corrosion inhibitor

MIL-PRF-81309H Types II & IV

Boeing Part No.: RMO 16679

Pratt & Whitney Part No.: PWC15-011

Cessna Spec: CSNP038, Type 9A

NATO NSO number 8030-01-438-4093

CorrosionX Aviation is globally recognised and trusted when it comes to the control and prevention of corrosion in aircraft.

The parrafin based product employs revolutionary Polar Bonding and Fluid Thin Film Coating (FTFC) technologies which cause it to stick to metal like a magnet. This drives out moisture and creates a thin, non-hardening, self-healing film which will creep into the hardest to reach cavity’s and voids. It is extremely resistant to wash-off and completely safe on rubber, neoprene, glass, plexiglass, all plastics, all paints, cabling and monofilament.

- Kills and prevents corrosion

- Long-lasting Polar Bonding Technology

- U.S. military proven to be more than 2X more effective* than other airframe corrosion prevention and control products

- Displaces moisture

- Penetrates and lubricates

- Self-curing Fluid Thin Film Coating (FTFC) technology

- Effective on all metals

- Safe on electronics

- Contains no waxes or silicones

- ZERO volatile organic content (other common airframe corrosion inhibitors contain as much as 5% VOC)

CorrosionX Aviation & Navguard Type IV are the only two products approved under the US Department of Defence MIL-PRF-81309H Type IV. This performance specification is for ultra-thin film, water-displacing corrosion preventive compounds. Products approved under this category must meet stringent criteria for corrosion protection (acid salt fog and neutral salt fog testing), max film thickness, max friction c-efficient and dielectric strength.

PRODUCT INFO

CorrosionX Aviation is the world's most trusted & proven aircraft corrosion inhibitor

MIL-PRF-81309H Types II & IV

Boeing Part No.: RMO 16679

Pratt & Whitney Part No.: PWC15-011

Cessna Spec: CSNP038, Type 9A

NATO NSO number 8030-01-438-4093

CorrosionX Aviation is globally recognised and trusted when it comes to the control and prevention of corrosion in aircraft.

The parrafin based product employs revolutionary Polar Bonding and Fluid Thin Film Coating (FTFC) technologies which cause it to stick to metal like a magnet. This drives out moisture and creates a thin, non-hardening, self-healing film which will creep into the hardest to reach cavity’s and voids. It is extremely resistant to wash-off and completely safe on rubber, neoprene, glass, plexiglass, all plastics, all paints, cabling and monofilament.

- Kills and prevents corrosion

- Long-lasting Polar Bonding Technology

- U.S. military proven to be more than 2X more effective* than other airframe corrosion prevention and control products

- Displaces moisture

- Penetrates and lubricates

- Self-curing Fluid Thin Film Coating (FTFC) technology

- Effective on all metals

- Safe on electronics

- Contains no waxes or silicones

- ZERO volatile organic content (other common airframe corrosion inhibitors contain as much as 5% VOC)

CorrosionX Aviation & Navguard Type IV are the only two products approved under the US Department of Defence MIL-PRF-81309H Type IV. This performance specification is for ultra-thin film, water-displacing corrosion preventive compounds. Products approved under this category must meet stringent criteria for corrosion protection (acid salt fog and neutral salt fog testing), max film thickness, max friction c-efficient and dielectric strength.

FEATURED PRODUCT

ANTI-STATIC PLEXIGLAS CLEANER, PROTECTANT & POLISH

A-Plex™ is an anti-static aircraft and marine Plexiglas cleaner, protectant and polish. Also excellent for use on motorcycle windscreens. A-Plex produces a microscopic, high lustre, soil retarding and water repellent finish to aircraft and marine plexiglass. A-Plex dries with no smears, no smudges and no oily residue. Can be applied in seconds. Suitable for use on BOEING LEXAN 9600 and GE-MR5 LEXAN.

KEY FEATURES

- Leaves a clean & lustrous finish with no smears, no smudges and no oily residue.

- Can be applied in seconds

- Fully certified for aviation use

WHY CHOOSE A-PLEX?

- Meets or exceeds the scope and performance requirements of MIL-C-878937 Type II

- Passes ASTM-F-484 Type A (stress crazing of acrylic plastic)

- Suitable for use on BOEING LEXAN 9600 and GE-MR5 LEXAN

- Passes ASTM F502, Standard Test Method for Effects of Cleaning and Chemical Maintenance Materials on Painted Aircraft Surfaces

Applications

Single Engine & Light Twins

Use CorrosionX Aviation or Navguard to protect

– wing sections

– fuselage

– vertical & horizontal stabilizers

– hinges

– Teleflex cables

– air vent cables

– trim cables

– throttle cables

– battery boxes

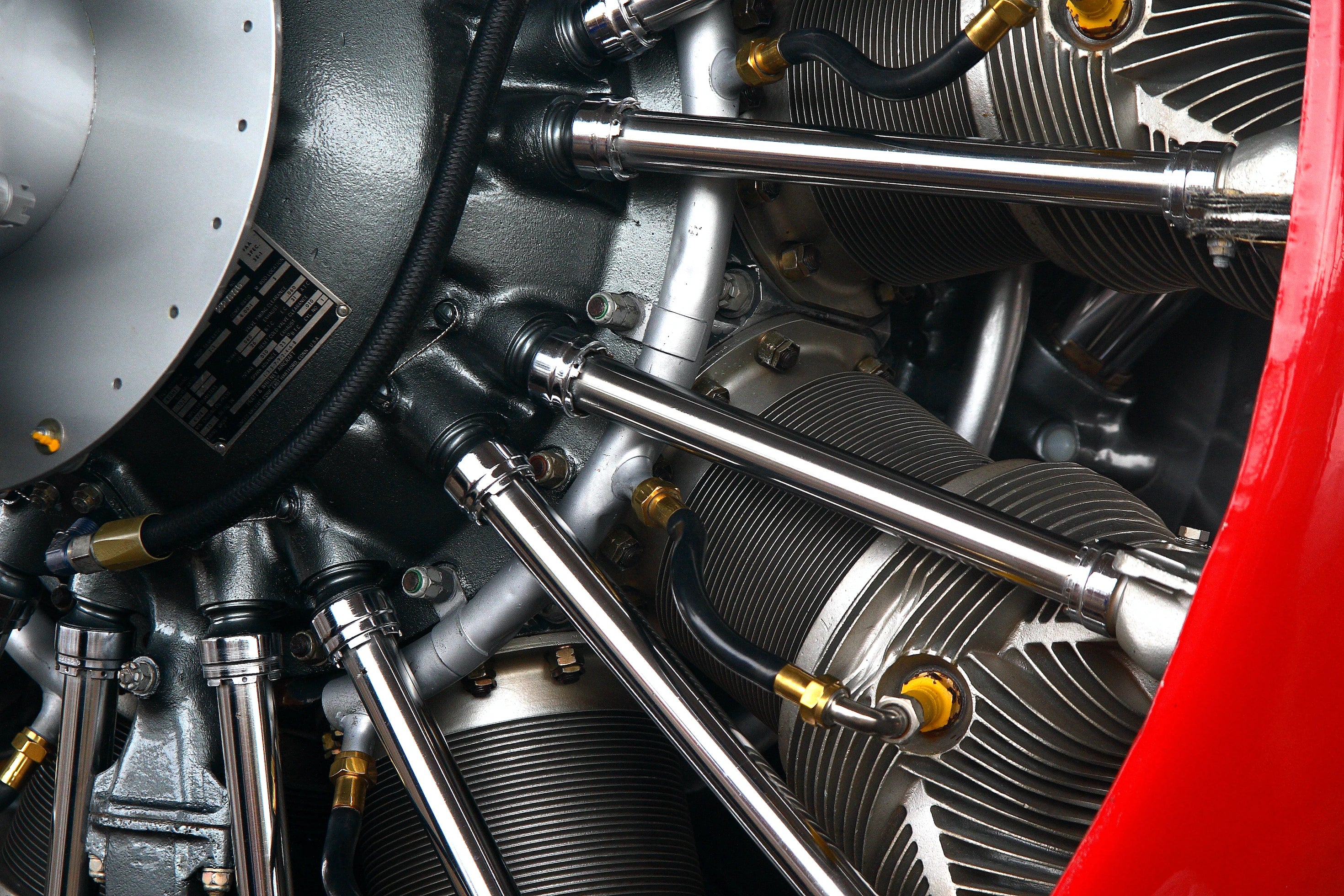

– engine compartments

– avionics

– antenna mounts

Rotor wing Aircraft

Use CorrosionX Aviation or Navguard to protect

– tail boom section

– engine compartments

– strap pack

– landing gear

– air vent cables

– rotor head

– grip areas

– avionics

– antenna mounts

– Cannon plugs

– Spray or wipe on blades.

Cargo Airlines

Use CorrosionX Aviation or Navguard to protect

– wing sections

– fuselage

– vertical & horizontal stabilizers

– landing gear compartments

– micro switches

– avionics

– cannon plugs

– cargo door brackets

– galleys

– lavatory areas

– belly skin sections

– main spar sections

Float Equipped & Amphibious

Use CorrosionX Aviation or Navguard to protect

– floats, fuselage

– vertical & horizontal stabilizers

– wing sections

– bilge area

– exterior of motors

– connectors

– cannon plugs

– avionics

– micro switches

– antenna mounts

Turbo Props/Business Jets

Use CorrosionX Aviation or Navguard to protect

– trim drum actuators

– micro switches

– landing gear & compartments

– wheel hubs

– thrust reverse mechanisms

– Wipe on nacelles

Aircraft surface cleaning & degreasing

Xhaust & Soot Remover is a powerful, concentrated, multipurpose aircraft cleaner / degreaser was specifically formulated to clean the toughest exhaust soot, belly grime and bug splats – all while being gentle on all aircraft surfaces. Meets BOEING D6-17487 REVISION R

Boot Klean is specifically designed to clean de-icing boots, which can then be sealed/protected by Boot Sealant.

Protective Coatings

Aero-Glide is a waterless dry wash. It is specially formulated with a blend of deep cleaners and light oxidation removers to provide a true one-step cleaning, detailing and polishing solution that leaves a high gloss protective finish on aircraft and other vehicles. Aero-Glide's hard protective coating reduces surface friction and exhaust stains.

RejeX is a thin-film polymer coating designed to provide a high-release protective finish for vehicles of all kinds. This very thin film – less than a micron thick – prevents stains and adhesion of common contaminants such as jet turbine exhaust, bugs on leading edges, oil, belly grime, etc.

Boot Sealant seals & protects de-icing boots. Designed to be used after boots have been cleaned with Boot Klean.

Helicopters

Navguard is ideal to protect industrial, medical, military & offshore helicopters

Military Aircraft

Navguard was designed by the US Navy to provide long lasting protection from corrosion for military aircraft.

Use Type II on moving parts where some lubrication is required, such as hinges, bomb racks and sliding parts.

Use Type I in areas at risk from fungi, moulds and mildew.

Use Type IV in corrosion prone areas.

Protection of machined parts

Navguard is ideal for protecting manufactured metal products during transport and storage

Acidic Environments

Navguard will provide corrosion protection in acidic environments such as water and sewage treatment facilities

FAQ'S

Are there any harmful ingredients in CorrosionX ?

Not in the recommended application quantities. It’s one of the safest products of its kind. The SDS addresses this question further for corporate, military, or aviation concerns.

How does CorrosionX compare with wax coatings?

Wax CPC’S are designed to prevent rust/oxidation, not interrupt it. They can create problems by covering up the compromised areas, allowing it to grow underneath. Furthermore, it’s possible for moisture to penetrate through the wax and allow rust to form. Wax products are also extremely high in VOC.

Can I safely use the products for my helicopter?

You can use CorrosionX Aviation for any Aviation machines.

Can I use the products on circuit boards?

Circuit boards are a great place to apply CorrosionX . If they are corroded or have moisture causing problems, CorrosionX usually restores them.

Perfect for drones, VHF’s, fuse boxes, deck switches and aviation instrumentation.

Can you paint over CorrosionX?

No, it must be removed which isn’t easy because of polar bonding. A good solvent or “stream jenny” (if a large area is involved) is required. MEK is the best remover but use with caution because it is a carcinogen and will remove paint. Acetone is also a good choice

How much should I use?

Use sparingly. Apply just enough so that you can see it is present.

Is CorrosionX flammable?

No, but the aerosol product is combustible. In aerosols, the propellant is propane which is very flammable so caution must be used if it’s sprayed into an area where there may be sparks.

What is Polar Bonding?

This is an electrostatic attraction to metal surfaces by some of the components found in CorrosionX. Most people understand polarity because they see it all the time on battery terminals and know the colour codes that denote plus/minus. Some of the molecules present in CorrosionX have polarity and the law of attraction between positive and negatives applies.

What’s the shelf life?

The product has unlimited shelf life. Will not go hard, gunk up or develop a skin in open top containers.It will not evaporate.

Why does CorrosionX penetrate so efficiently?

This characteristic of CorrosionX is enhanced by the polar bonding along with capillary action. The product spreads until it reaches its minimum thickness and, at the same time, frees seized parts as oxides are softened up in the process. If you looked at mating surfaces under a microscope you would see “asperities” or surface roughness that appears to be similar to “microscopic mountains”, that allow creeping to take place no matter how tightly joined. These microscopic voids aid in allowing the product to travel.

Why doesn’t CorrosionX interfere with electrical connections?

CorrosionX will not interfere with electrical components even though it has an extremely high dielectric rating of 36,000 volts. The reason is that the film thickness at less than one mil is not sufficient to insulate. CorrosionX can actually enhance circuitry by lubricating switches and removing light corrosion at the same time