Corrosion protection for harsh marine environments

Corrosion Protection

Other Commercial Marine Products

KEY USES

Container Cranes

CorrosionX Grease is used to lubricate the wire ropes on container cranes at all major NZ ports because it extends the life of the wires. CorrosionX grease sticks to the crane wires at a molecular level, providing long lasting lubrication and corrosion protection that won't flick off & block critical sensors.

Straddle Carriers & Forklifts

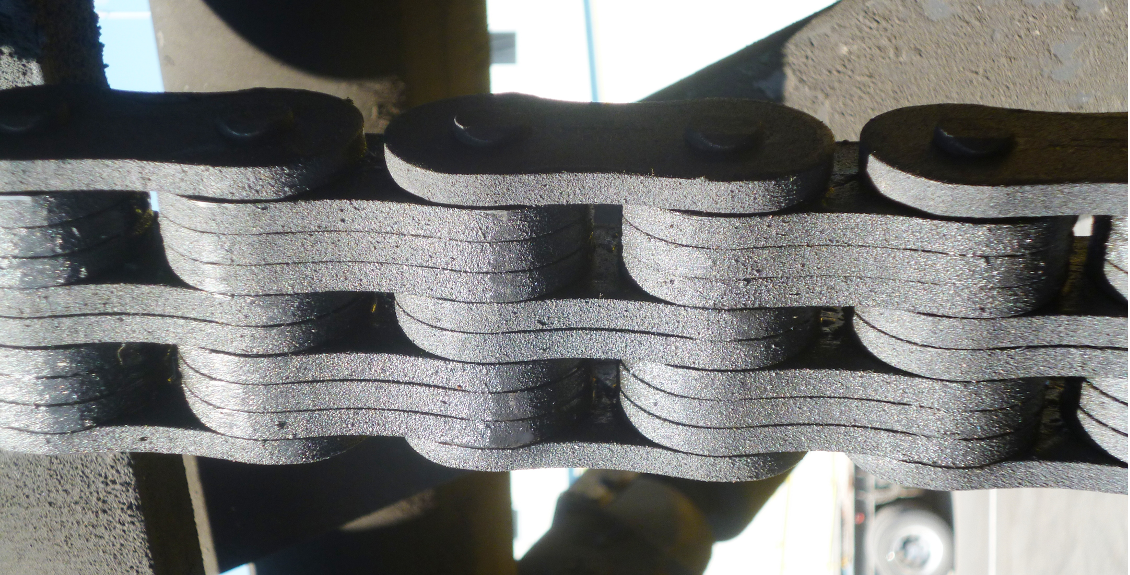

CorrosionX HD is used to lubricate lifting chains at ports around NZ. CorrosionX HD never dries out and sticks to the wires via polar bonding. It is highly resistant to wash off & provides lasting lubrication & corrosion protection in the harshest environments. CorrosionX HD protects against pin movement and enables longer service intervals.

Bilges, Bilge Keels & Voids

MaxWax™ is a wax based corrosion inhibitor barrier coating with time release Vapor Corrosion Inhibitor (VCI) technology. MaxWax provides long lasting protection from corrosion in confined spaces such as bilge keels, vessel bilges, tug voids, electrical cabinets and tool boxes

The photo shows our grease being applied by Shaw Wires at the Ports of Auckland.

"CorrosionX grease penetrates to the core of the rope providing complete lubrication. It is also excellent as a penetrating lubricant for chains of all sizes. The grease stays on the rope and therefore keep the cranes clean.

We recently won a contract with a big port company that specify that only CorrosionX must be used on their ropes. We introduced CorrosionX grease to this company 5 years ago - one happy customer!"

Bertus Marks, Shaw's (www.shaws.co.nz)

CorrosionX Grease application by Viper

PRODUCT INFO

CORROSION PROTECTION FOR HARSH MARINE ENVIRONMENTS

CorrosionX® is the most advanced and effective corrosion prevention compound, lubricant and penetrant in the world. It was designed with harsh coastal and maritime climates in mind.

As a Corrosion Inhibitor…

Although it might look similar to other oil-based anti-corrosion sprays, CorrosionX utilises revolutionary Polar Bonding™ and Fluid Thin Film Coating (FTFC™) technologies that together do far more than merely slow down the corrosion process like other so-called 'corrosion inhibitors'. CorrosionX actually disrupts rust and corrosion on the molecular level (displacing it from the metal surface and keeping it from spreading) and provides long-term protection against rust and corrosion on any metal surface.

As a Lubricant….

CorrosionX's unique formulation offers a multitude of advantages over conventional lubricants. Because Polar Bonding causes it to stick to metal like a magnet, it cannot be easily displaced by pressure, friction or moisture. It lubricates under extreme loads and high temperatures. Not only does CorrosionX lubricate better, it lasts many times longer. This is especially true in outdoor, coastal and marine environments where direct exposure to rain and sea spray will quickly displace ordinary lubricants.

As a Penetrant….

CorrosionX penetrates faster and further than any penetrating fluid you've ever used. Corroded or rusted nuts, bolts or fittings can usually be disassembled within minutes. Even items you believe to be hopelessly seized can usually be saved and returned to service.

PRODUCT INFO

CORROSION PROTECTION FOR HARSH MARINE ENVIRONMENTS

CorrosionX® is the most advanced and effective corrosion prevention compound, lubricant and penetrant in the world. It was designed with harsh coastal and maritime climates in mind.

As a Corrosion Inhibitor…

Although it might look similar to other oil-based anti-corrosion sprays, CorrosionX utilises revolutionary Polar Bonding™ and Fluid Thin Film Coating (FTFC™) technologies that together do far more than merely slow down the corrosion process like other so-called 'corrosion inhibitors'. CorrosionX actually disrupts rust and corrosion on the molecular level (displacing it from the metal surface and keeping it from spreading) and provides long-term protection against rust and corrosion on any metal surface.

As a Lubricant….

CorrosionX's unique formulation offers a multitude of advantages over conventional lubricants. Because Polar Bonding causes it to stick to metal like a magnet, it cannot be easily displaced by pressure, friction or moisture. It lubricates under extreme loads and high temperatures. Not only does CorrosionX lubricate better, it lasts many times longer. This is especially true in outdoor, coastal and marine environments where direct exposure to rain and sea spray will quickly displace ordinary lubricants.

As a Penetrant….

CorrosionX penetrates faster and further than any penetrating fluid you've ever used. Corroded or rusted nuts, bolts or fittings can usually be disassembled within minutes. Even items you believe to be hopelessly seized can usually be saved and returned to service.

Applications

Container cranes

CorrosionX Grease is used to lubricate the wire ropes on container cranes at all New Zealand’s major ports because it extends the life of the wires. CorrosionX Grease sticks to the crane wires at a molecular level, so our grease provides long lasting lubrication and corrosion protection and will not flick off and block critical sensors.

CorrosionX Grease is suitable for all types of wire rope applications, port cranes, straddle wire ropes, mobile crane wire ropes and tower crane wire ropes. CorrosionX Grease penetrates between the strands to the core of the rope providing complete rope lubrication. It reduce friction between the sheaves and rollers on cranes which help with a smoother operation.

Proper lubrication of wire ropes will safely extend operational life, regardless of applications.

Marine cranes are exposed to harsh environmental conditions, including extreme weather. CorrosionX has excellent corrosion resistance and high load carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary.

CorrosionX Grease is Viper-approved.

Straddle carriers & forklifts

Corrosion X HD is used to lubricate the lifting chains at ports around New Zealand. CorrosionX HD is highly resistant to wash off (persisting after 2,000 hours salt spray testing) so it provides longer lasting lubrication and corrosion protection in the harshest environments.

Because it never dries out and sticks to the wires at a molecular level, CorrosionX HD protects against pin movement and enables longer service intervals. CorrosionX HD does not pick up dust, debris or salt

Bilges, bilge keels & voids

MaxWax™ is a wax based corrosion inhibitor barrier coating with time release Vapor Corrosion Inhibitor (VCI) technology. MaxWax provides long lasting protection from corrosion in confined spaces such as bilge keels, vessel bilges, tug voids, electrical cabinets & tool boxes. Requires surface cleaning & preparation. The Royal New Zealand Navy uses MaxWax to protect the bilge keel of the frigate Te Kaha.

CorrosionX XD is alternative option for corrosion protection in bilges & voids. CorrosionX XD penetrates existing rust and corrosion, displaces moisture and prevents electrolysis. It leaves a non-hardening, self-healing coating for maximum protection against moisture intrusion. Performs on already wet and corroded surfaces.

Hydraulic fittings

CorrosionX XD and MaxWax provide long lasting corrosion protection on hydraulic fittings. An alternative to Denso tape that does not impede visual monitoring

Wire ropes

CorrosionX Grease is suitable for all types of wire rope applications, port cranes, straddle wire ropes, mobile crane wire ropes and tower crane wire ropes. Due to its polar bonding properties, the grease stay on the rope and therefore keep the cranes clean.

CorrosionX Grease penetrates between the strands to the core of the rope providing complete rope lubrication. It reduce friction between the sheaves and rollers on cranes which help with a smoother operation. Proper lubrication of your wire rope can safely extend its operational life regardless of applications.

CorrosionX Grease has excellent corrosion resistance and high load carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary. It is also excellent as a penetrating lubricant for chains of all sizes.

CorrosionX HD is an excellent lubricant for smaller diameter wires and provides long lasting corrosion protection for stored wires.

Both CorrosionX Grease and CorrosionX HD are Viper-approved.

Assembly compound & anti-galling agent

CorrosionX HD is an unparalleled lubricant and is perfect as an assembly compound in the workshop.

CorrosionX HD is also a great anti-galling agent. Heron Construction uses CorrosionX HD to prevent galling of the large stainless steel bolts used in wharf construction.

Water-proofing electronics

CorrosionX is great for water-proofing electronics that are exposed to moisture and the elements.

CorrosionX won’t short sensitive circuits or interfere with electrical

connections. It displaces moisture and existing corrosion, cleans

contact points and improves connectivity – often restoring electronics that have been exposed to moisture and the elements.

CorrosionX HD - the ideal lubricant for lifter chains

BEFORE - Hyster Container Lifter chain while using oiler system/engine oil for lubrication in Ports of Nelson

AFTER - Same chain 14 weeks into using CorrosionX Heavy Duty single application

Before

After

FAQ'S

Are there any harmful ingredients in CorrosionX ?

Not in the recommended application quantities. It’s one of the safest products of its kind. The SDS addresses this question further for corporate, military, or aviation concerns.

How does CorrosionX compare with wax coatings?

Wax CPC’S are designed to prevent rust/oxidation, not interrupt it. They can create problems by covering up the compromised areas, allowing it to grow underneath. Furthermore, it’s possible for moisture to penetrate through the wax and allow rust to form. Wax products are also extremely high in VOC.

Can I safely use the products for my helicopter?

You can use CorrosionX Aviation for any Aviation machines.

Can I use the products on circuit boards?

Circuit boards are a great place to apply CorrosionX . If they are corroded or have moisture causing problems, CorrosionX usually restores them.

Perfect for drones, VHF’s, fuse boxes, deck switches and aviation instrumentation.

Can you paint over CorrosionX?

No, it must be removed which isn’t easy because of polar bonding. A good solvent or “stream jenny” (if a large area is involved) is required. MEK is the best remover but use with caution because it is a carcinogen and will remove paint. Acetone is also a good choice

How much should I use?

Use sparingly. Apply just enough so that you can see it is present.

Is CorrosionX flammable?

No, but the aerosol product is combustible. In aerosols, the propellant is propane which is very flammable so caution must be used if it’s sprayed into an area where there may be sparks.

What is Polar Bonding?

This is an electrostatic attraction to metal surfaces by some of the components found in CorrosionX. Most people understand polarity because they see it all the time on battery terminals and know the colour codes that denote plus/minus. Some of the molecules present in CorrosionX have polarity and the law of attraction between positive and negatives applies.

What’s the shelf life?

The product has unlimited shelf life. Will not go hard, gunk up or develop a skin in open top containers.It will not evaporate.

Why does CorrosionX penetrate so efficiently?

This characteristic of CorrosionX is enhanced by the polar bonding along with capillary action. The product spreads until it reaches its minimum thickness and, at the same time, frees seized parts as oxides are softened up in the process. If you looked at mating surfaces under a microscope you would see “asperities” or surface roughness that appears to be similar to “microscopic mountains”, that allow creeping to take place no matter how tightly joined. These microscopic voids aid in allowing the product to travel.

Why doesn’t CorrosionX interfere with electrical connections?

CorrosionX will not interfere with electrical components even though it has an extremely high dielectric rating of 36,000 volts. The reason is that the film thickness at less than one mil is not sufficient to insulate. CorrosionX can actually enhance circuitry by lubricating switches and removing light corrosion at the same time

FEATURED PRODUCT

MARINE SCALE & GROWTH DISSOLVER

BARNACLE-X is the only biofouling remover which targets the complete range of issues associated with fouling organisms and the dissolved minerals contained in fresh, brackish and seawater.

BARNACLE-X dissolves calcium- & silicone dioxide-based shells and exoskeletons; mineral accumulations; and the bio-adhesives secreted by barnacles, mussels and limpets, enabling those organisms to be quickly and easily removed from vessel hulls and running gear.

KEY FEATURES

- For use on both freshwater & saltwater systems & hulls

- Dissolves the calcium and silicone dioxide shells and exoskeletons of macrofouling organisms such as barnacles, mussels, limpets and coral, as well as microfouling organisms such as bacteria and algae that accumulate on heat exchanger surfaces.

- Contains the natural release agent for the bio-adhesives secreted by barnacles and mussels.

- Reduces corrosion caused by restricted flow, the anodic condition created by decreased oxygen below the fouling layer, and the metabolic by-products of bacteria.

- Safe on bronze, copper, gelcoat and marine paints when used as directed

- The Best Value: Dilutes up to 5:1 with water

WHY CHOOSE BARNACLE-X?

- THE ONLY BARNACLE BUSTER PRODUCT WITH TRI-ACTION

- Dissolves calcium- & silicone-based shells & exoskeletons

- Targets the bio-adhesives that barnacles and mussels use to attach

- Dissolves algae, coralline and mineral scale

USES

- Cleaning heat exchangers on water-cooled engines

- Cleaning heat exchangers on marine air conditioners

- Clearing restricted pipework and valves

- Removing macrofouling (ex: barnacles, mussels & limpets) and other hard fouling from boat and ship hulls and running gear